Making Segmented Elbows for CNC plasma cutting

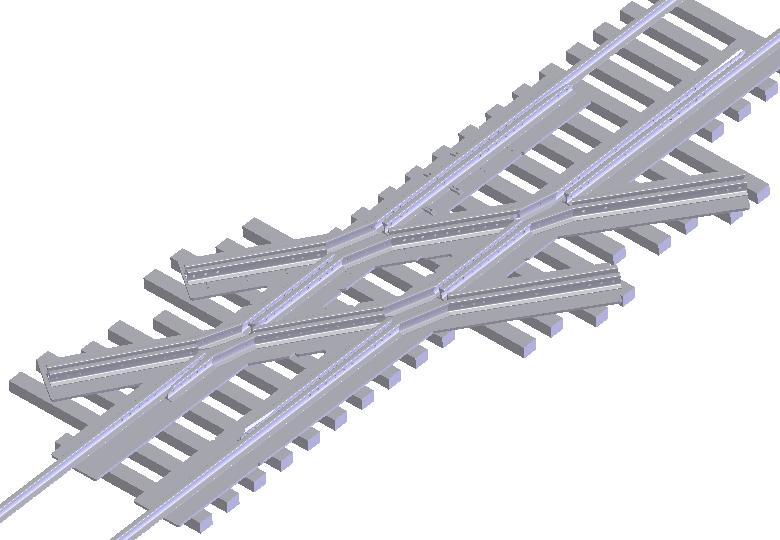

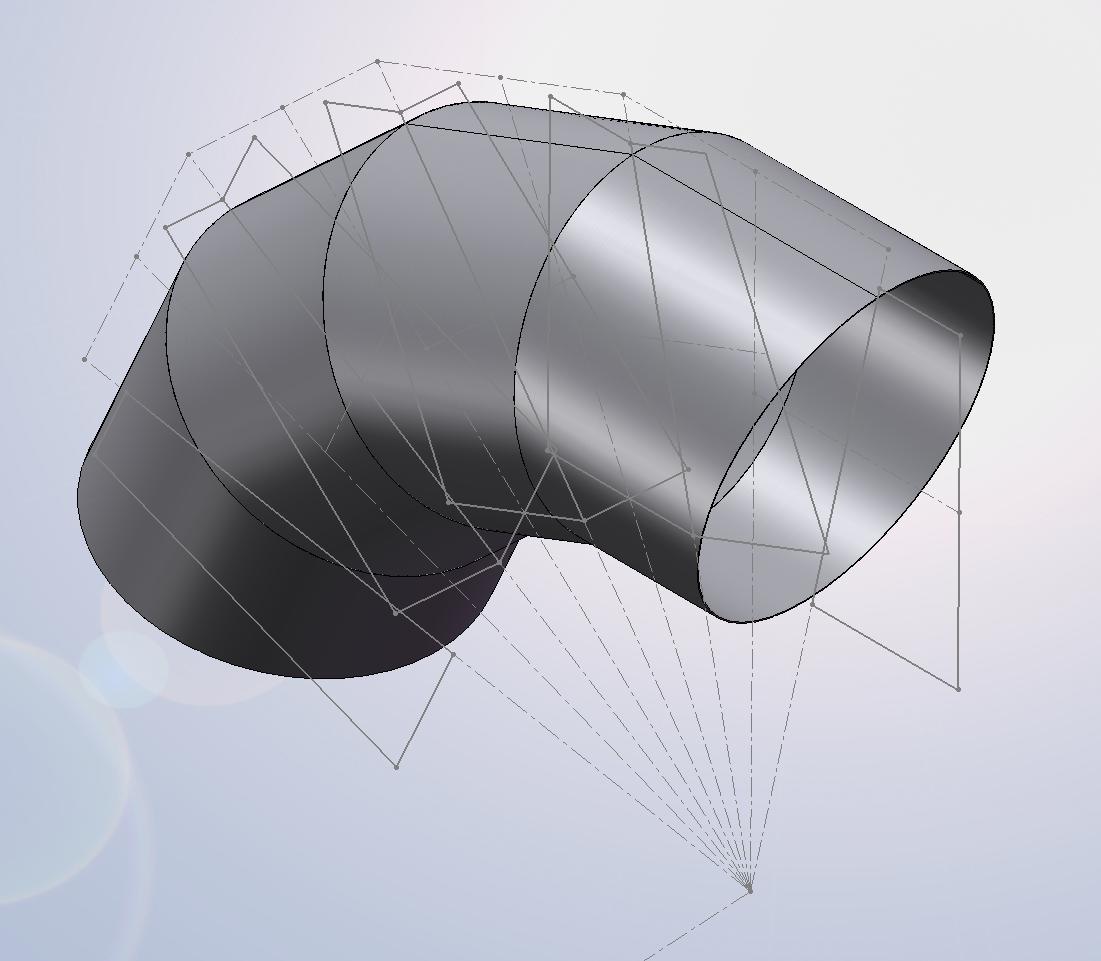

Segmented elbows or Gored elbows are typically used on duct systems when you have large diameter duct but need an economical way to fabricate the elbow. Usually this is achieved by making the elbow in segments. For example A 90 degree 30 inch segmented elbow might be made in 4 segments of 22.5 degrees each.

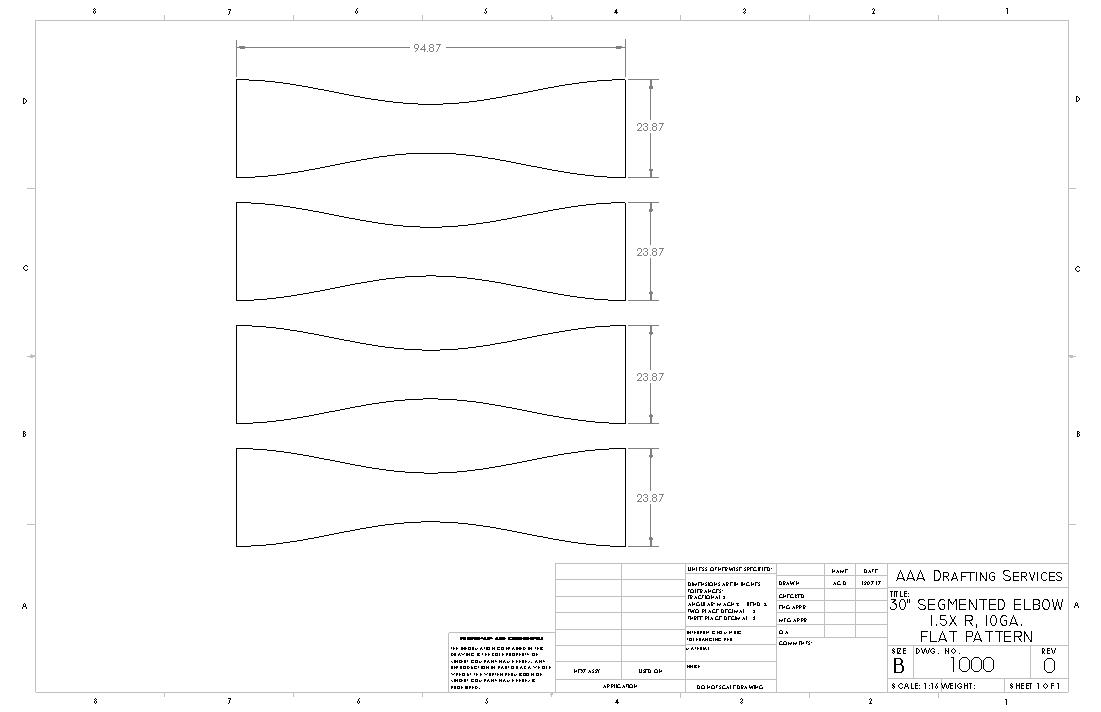

Each segment is made from a flat sheet of steel that is cut to size and shape using a CNC plasma cutting table. Then rolled into a 30 inch diamter duct segment. To finish the elbow, the 4 segments are welded together

Large elbows using steel thicker than 18 gauge are typically welded together. Smaller segmented elbows can be made from thinner sheet metal and instead of welded construction the elbow segments have extra material left on them so that a lockforming machine can be used to join them together. Elbows that are joined together by this method are usually called Gored segmented elbows.

The segmenting is also done to help keep friction to a minimum in the elbow. The friction in the segments is higher than with a totally smooth elbow but its still an acceptable compromise because the elbow is easier to fabricate

Segmented elbows are less expensive to fabricate because they can be made from inexpensive steel sheets. But they have to be cut specially so the segments fit together perfectly. In the past flat sheet development was done by hand by the sheet metal fitter or a draftsperson. It was a time consuming process.

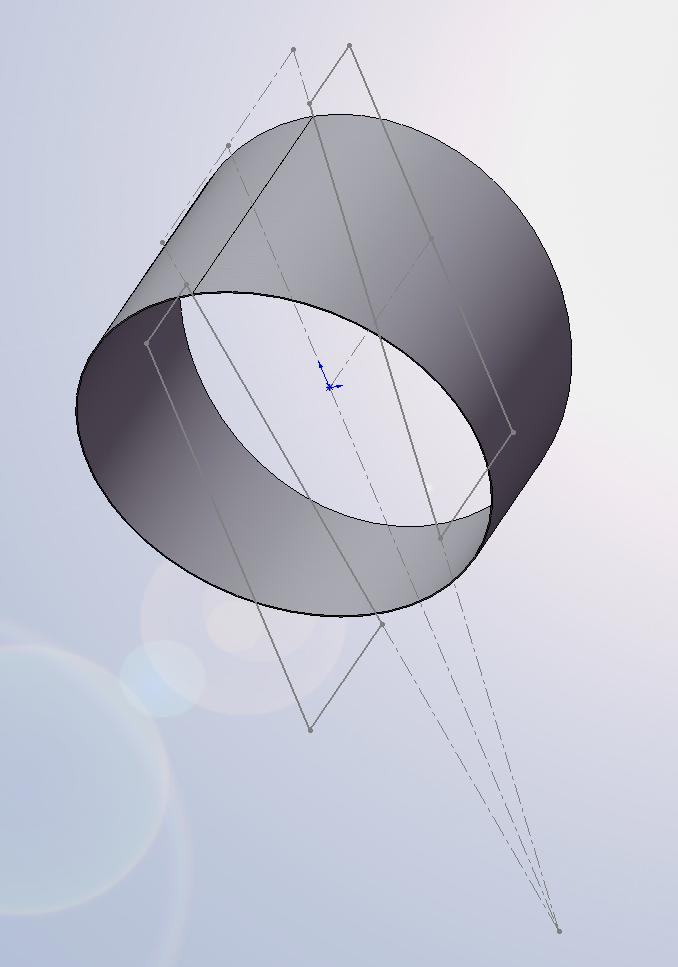

Now with 3D modelling and sheet metal unwrapping tools its a whole lot easier. As well, cutting is a lot more precise and predicatable using CNC plasma cutting tables, which can cut all four pieces of a segmented elbow at the same time, all exactly alike.

Manual cutting of elbow segments can still be done using a printed CAD drawing made at full scale as a template. The printed template is laid on top of the sheet metal and the fitter can mark and transfer the curves to the sheet metal for hand cutting.

AAADrafting can make models and flat development drawings of segmented of any type or description that make it as easy as possible for you to fabricate.