Material Recovery Facilities Drafting

Author Harvey Alter. See more information in the book summary below

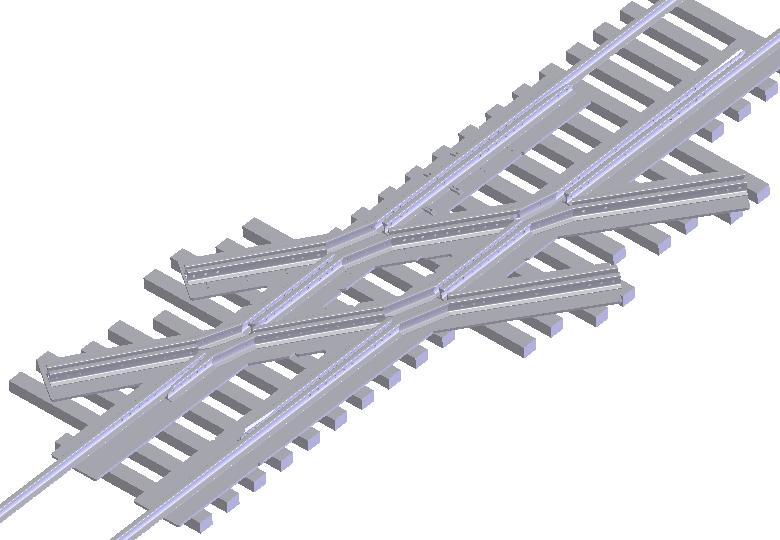

Material recovery facilities layout is key for getting the maximum benefit from new recyclables sorting equipment and technologies. There are a number important issues to be addressed in addition to the equipment itself if recycling is to become a profit center.

There should be plenty of capacity for trucks and loaders, Tipping areas and push walls at material recovery facilities need to be laid out carefully as well as the optimum locations for totes and storage of recycled fractions. Vermin and odour control measures all must be factored in as well.

The material recovery facility

Getting trucks through the recycling center efficiently is important as recycling vegicles all tend to arrive at the same time. An efficient layout is necessary to allow them to get in, dump their load on the tipping floor and get out quickly. The material recovery facility itself must be made as open as possible so there is less possibility for fork lifts and trucks to run into and damage building columns.

Strong concrete reinforced bollards are also needed at all entrances and exits used by trucks. No one wants to shut down the facility while you wait to fix broken door. There must be enough height in the building to allow trucks to tip their loads properly, and enough height to allow them out should they forget to lower their loads!

One method to reduce the problems of vermin is to eliminate pits and recesses for conveyors and equipment. Any cavity where garbage can accumulate will become attractive to vermin and rodents. Pits are also expensive pieces of concrete work so anything that can be done to eliminate them will also reduce cost. It's also important to eliminate drains from the tipping floor area. These will invariably clog with garbage and quickly become unuseable.

The floor of the material recovery facility itself requires careful consideration. In Wet/Dry recycling facilities the Wet or MSW tipping floor needs to be acid resistant concrete to cope with the lecheate it will be exposed to. Tipping floor concrete should also be extra hard to stand up to the constant scraping from heavy front end loaders. An alternative is to allow a layer of asphalt on top of regular concrete. This asphalt needs replacement every 4 to 5 years but is much less expensive to maintain than concrete surfaces are.

A good layout for the proposed MRF will is a first step in creating a building that will address the need needs of the waste reduction plan in the city or municipality and will also go a long way in making the facility a potential profit center by providing property sorted materials for reuse.

About the book

The book shown in the upper right corner is written by Harvey Alter an adjunct professor at American University in Washington D.C. He is a recognized expert in the materials recovery field and has authored more than 80 papers on the subject.

His book covers the caveats of materials recovery and discusses the pros and cons of the technology required to split waste down into different fractions. It talks about Air classification, Iron and Steel recovery and recovery of aluminum based materials. It also discusses the methods used for deriving fuel from waste.

There are also sections on testing and evaluation methods for waste transfer facilities as well as methods to assess the risk of waste management projects. The book would be extremely useful to anyone involved in the planning of new materials recovery facilities.