Ducting system design & detailing

Ducting system design is a must for productivity as well as employee health and safety in dust collection. There are many poisonous, toxic and dangerous dusts and mists that need to be controlled and kept out of breathing space. Free flying dust is also product that needs be recaptured by the ducting system and recycled back into the production process.

At each stage in the system from the colection point on back to collector the duct work has to be carefully planned out so it is easy to assemble, properly supported and keeps the area clean and free from airborne dust.

Dust collection works best when the same high air velocity is maintained throughout the system. Typically, dust collection duct work is intended to provide for 3500 feet per minute air velocity throughout the entire duct run. As we add collection points along the duct run, the area or size of the duct has to increase to allow the velocity to be maintained. The ductwork system is often "balanced" through the use of sliding "blast gates" at every pick up point in the system.

When flammable or explosize dusts are to be collected, the pick up velocity is increased to 4500 feet per minute and a whole host of safety regulations stipulated by the NFPA come in to play so that the risk of explosion or fire in the duct is minimized. Blast gates are often forbidden in these types of systems due to the risk of combustible material collecting at the blast gate.

The first part of the duct design process involves single line diagrams to lay out the path of the duct and come up with estimates on the required length and note obstacles such as walls and machinery that the duct must pass through or connect to.

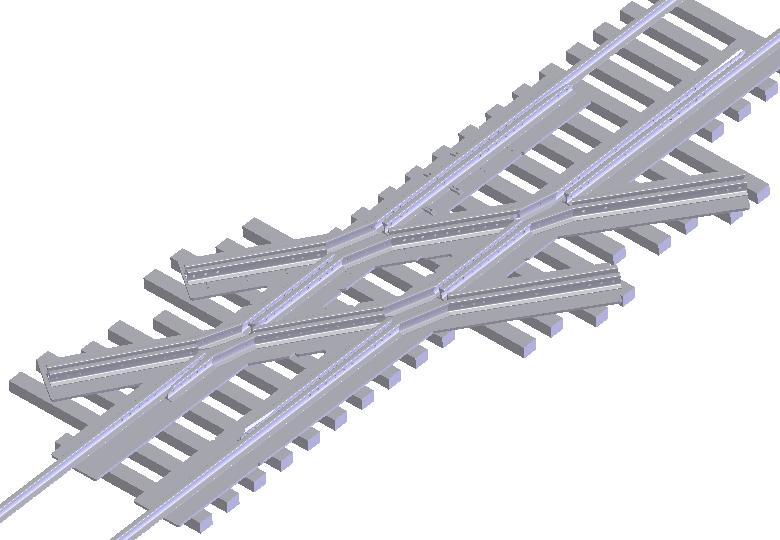

Nowadays we are not limited to fabricating duct systems out of spiral duct sections and rolled metal flanges. There are complete duct section packages with tees, wyes and branches that can be purchased in the exact size required. This can make the bulk of the dust collection system more economical and restrict the use of custom fabrication to only highly customized duct components. Examples might be systems for highly abrasize dusts in the Blasting and shot blast industries where abrasive resistant elbows are required with abrasion panels that can be periocally replaced.

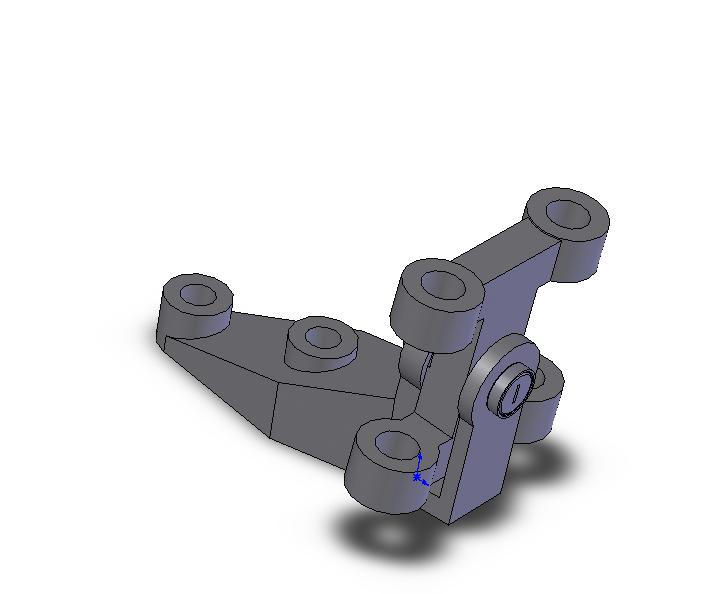

Another example might flexible dust collection connections to vibratory screens on the Cement & Concrete as well as Mineral processing industries.

Call for more information if you have and an industrial ventilation system problem