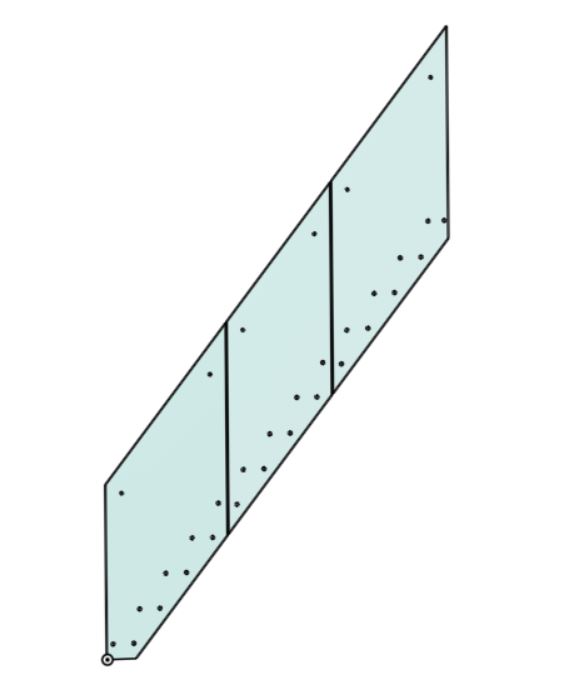

Glass railing design

Glass railing design is popular nowadays but it requires experience in assembling and fabricating with thick heavy sheets of glass. As well, you need to control costs since even with modern CNC glass cutting machines there is a lot of waste which the contractor has to pay for

Glass railing panels also have to be tempered which means they have to be accurately cut first time because the tempering process does not allow you to go back and make changes to the size of panels if they do no assemble correctly or if holes do not line up to stair treads.

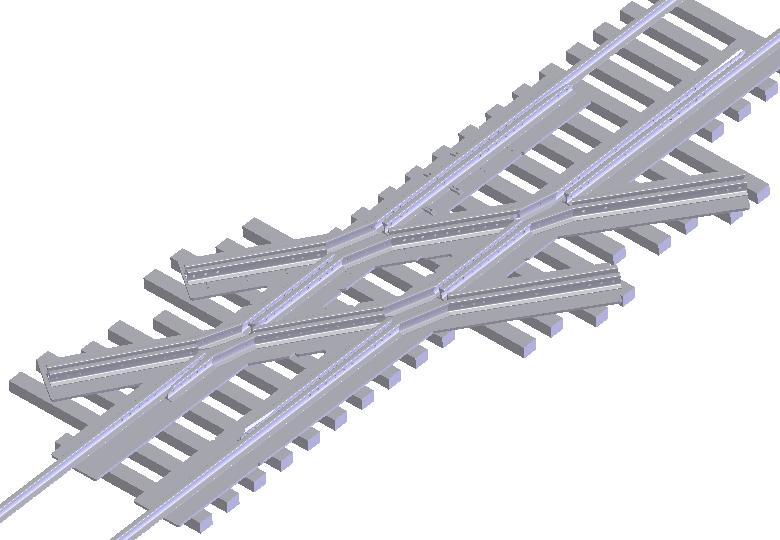

Designing for stair treads & handrails

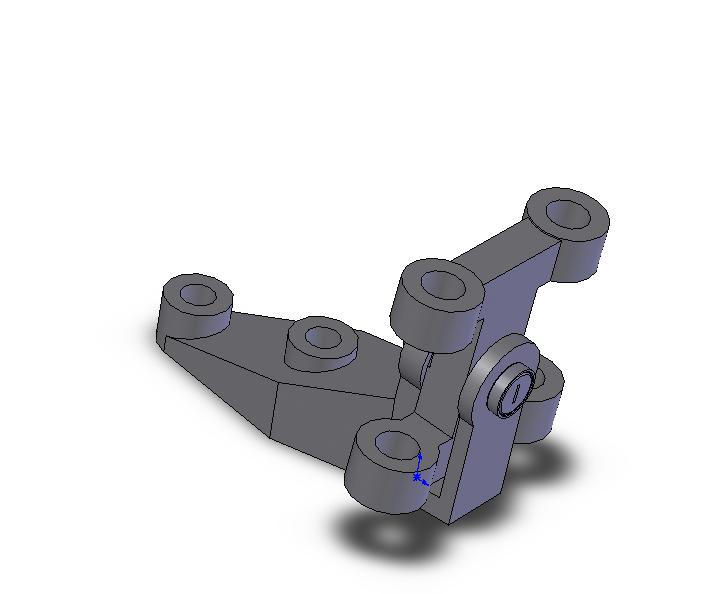

Glass railings are attached to the stairs using metal fasteners. The fasteners for stair treads and handrails require oversize holes to be made in the glass for plastic bushings. That way metal fasteners do not make contact with the glass. Tempered glass and metal really, really do not get along!

The oversize holes also accomodate minor adjustments necessary to align neighbouring glass panels as well as attachment points in stair treads that might be slightly off center due to site conditions. Rubber washers behind attachment screws secure against the face of the glass to hold it securely once adjusments are made

3d layout of the panels helps because you can visualize the installation of the panels to make sure there wont be any interference points. It also allows you to turn the glass panel drawings into DXF files which can be loaded directly into a CNC glass cutting machine.

CNC glass railing cutting problems

In some shops plywood templates are made to the exact size of the required glass railing, then these are photographed, the photos scanned and then the scans sketched over to provide CAD information for CNC glass cutting. This process can cause all sorts of errors.

By scanning digital photographs, errors can be caused by shadows and improper lighting of the plywood templates. The person sketching in CAD over top of a photograph, or the scanner reading a photo and recognizing the edges of the panel can mistake a shadow for an edge, causing expensive mistaken dimension errors.

To make this worse, the carpenter or contractor ordering the glass has to pay for the entire sheet of thick glass used in the cutting process including the scrap. Something that is often overlooked in price per square foot estimates. Stair panels are often irregular shapes that leave large amounts of offcuts. Its not uncommon for the price of a panel to be doubled due to scrap.

3D Design as a stair tool

3D design tools give the glass railing installer or carpenter a means to check fit and alignment before commiting to an expensive glass purchase. If panels dont align on the computer screen, measuring points can be rechecked. Measurements can be taken off the 3D model and verified in the field.

Providing the glass cutter with DXF files eliminates errors due to sketching over a photograph, or depending on scanning software to recognize edges. The best way to reduce errors, is to get the shape into the glass cutting software directly so that that the glass railing is cut exactly to the same dimensions as it was designed to.