Project Management Plan - Bascule Bridge Repair

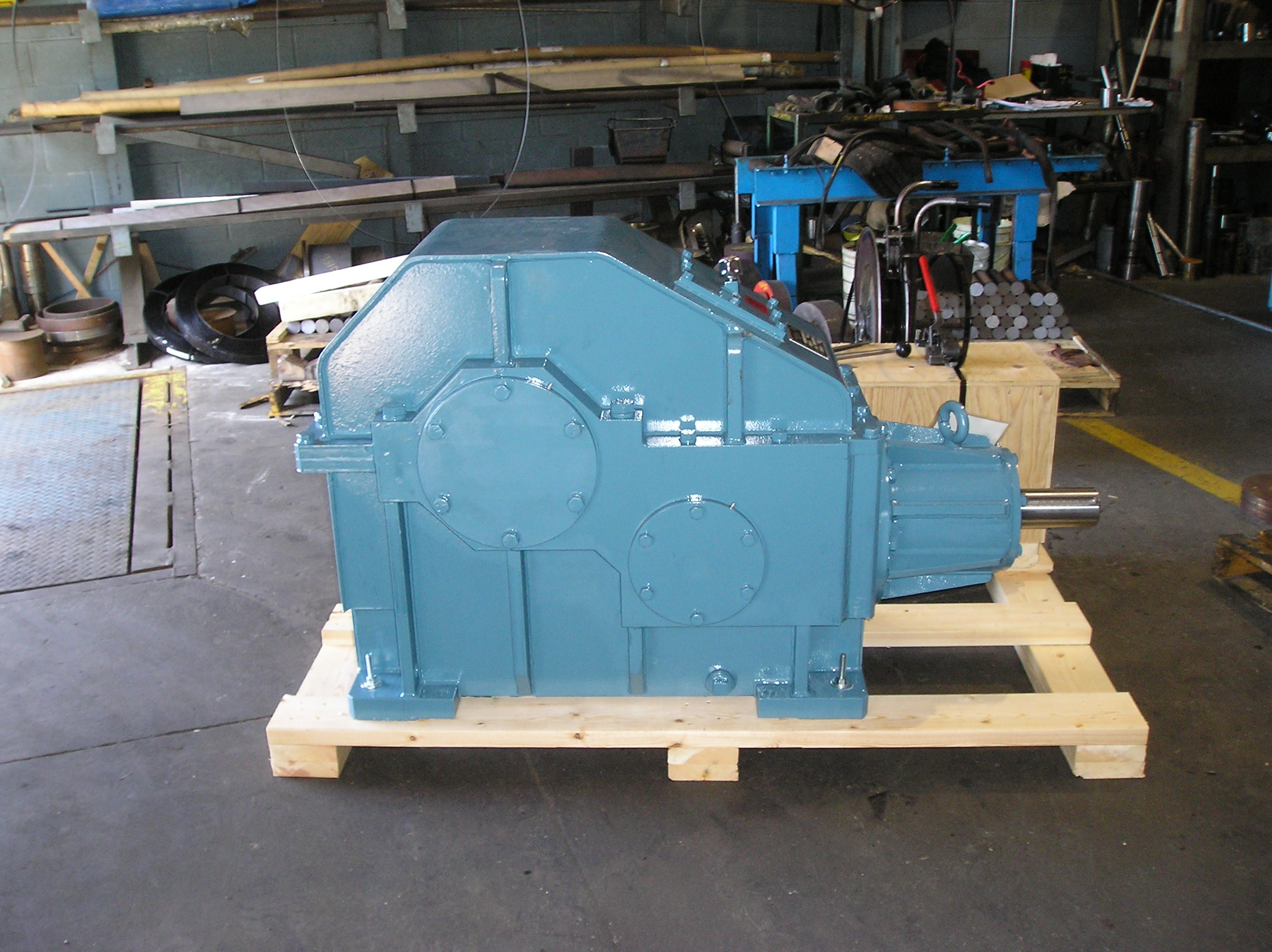

Project management plan - Bascule Bridge Repair. The challenge was to replace the main lift bridge gearbox in a 30 year old bascule bridge. The gearbox manufacturer had long since gone out of business so a custom gearbox had to be built using the original gearbox specifications and noting the special mounting conditions of the existing gearbox.

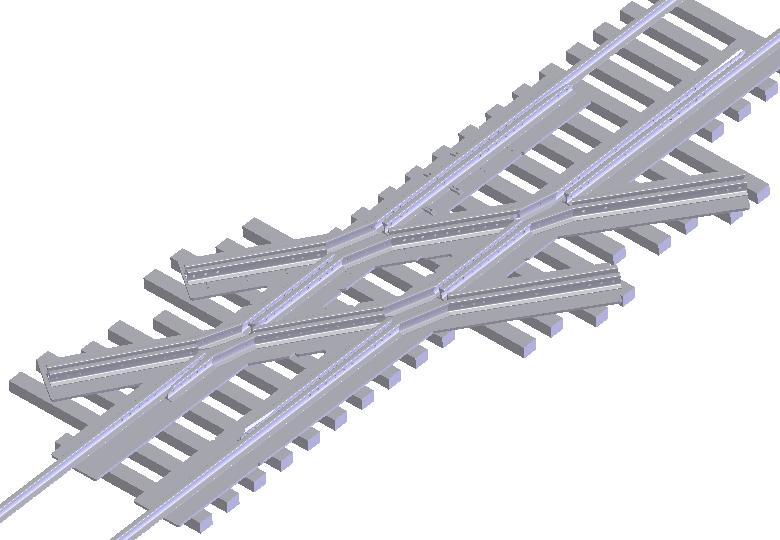

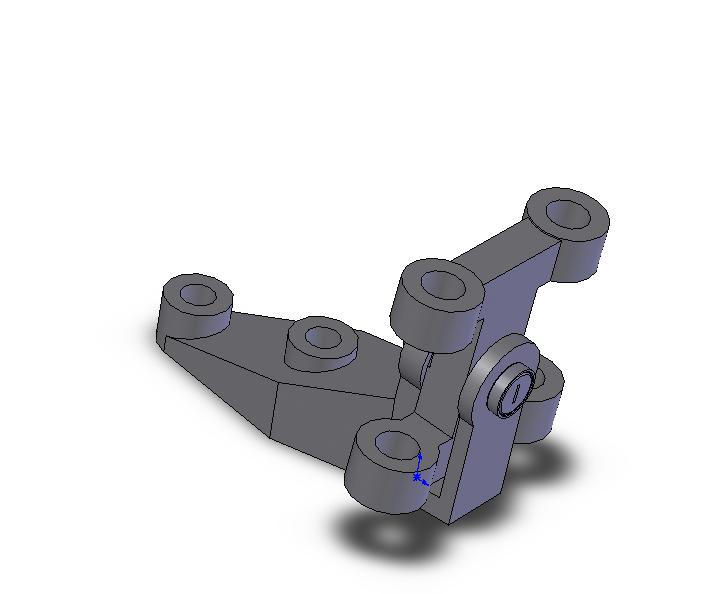

One important part of the plan was the fabrication of a special alignment jig. The alignment jig was used in place of the new gearbox, to make sure the new gearbox base was installed exactly in the right position. The alignment jig also allowed some leeway in the delivery of the new gearbox. The new gearbox could be received while the work was proceding on the installation of the new base.

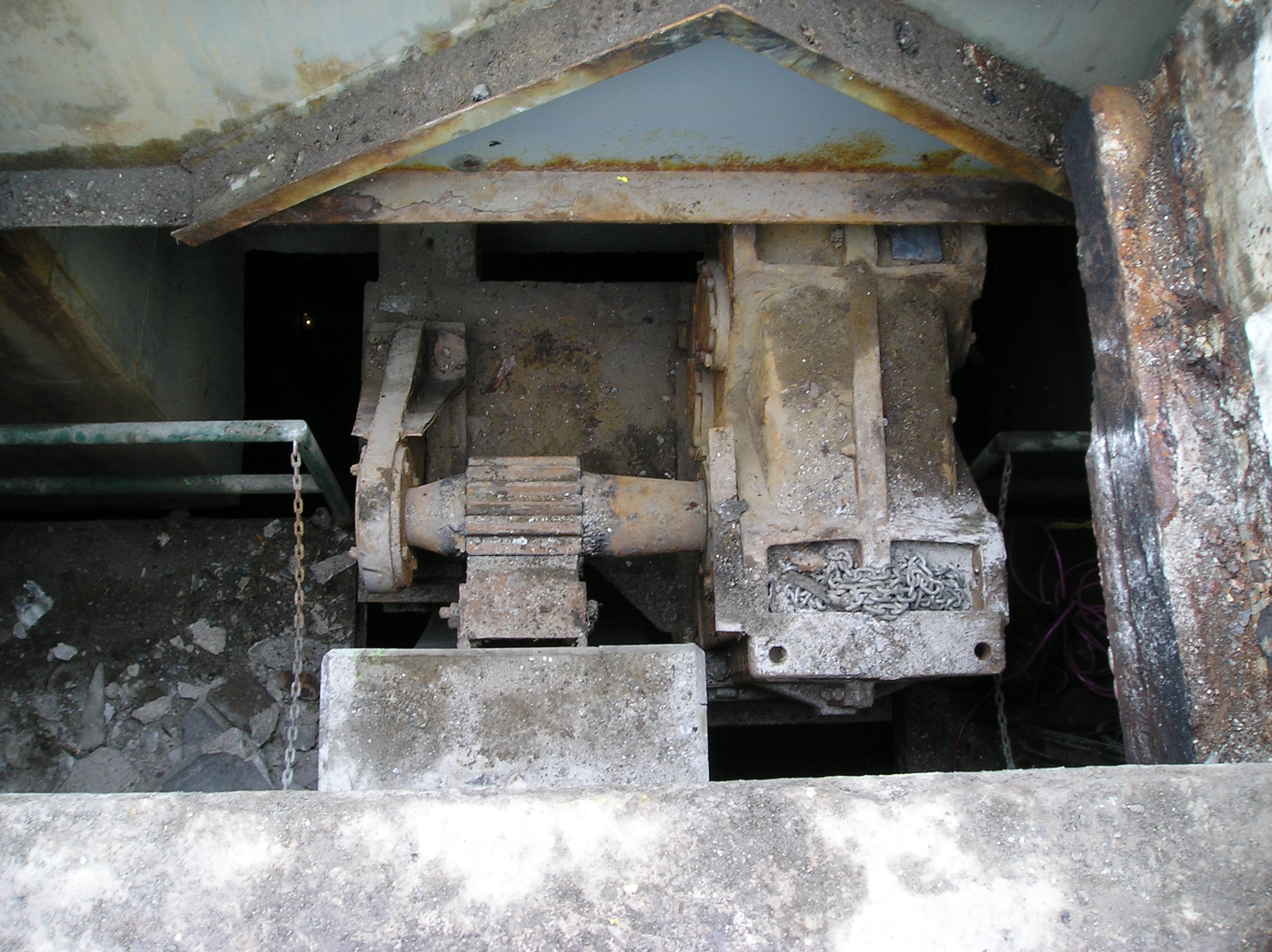

A concrete plug was removed to expose the old gearbox, pinion and bearing. The rusted condition of the old gearbox mount could well have impacted on the bridges safety in future years. Once the plug was removed, plans could be implemented to finally remove the old components from the bridge. It was determined the pinion would have to be cutoff the gearbox, in order to lift the gearbox through the opening.

The concrete plug presented some challenges on removal when one side broke off. A new concrete plug had to be fabricated quickly while the open hold was covered with a thicj steel plate. The steel plat allowed traffic to to pass while final alignment of the new gearbox was taking place. Note: 20 ton trucks crossing the bridge dont make life easy when aligning gearboxes !

The access hole with the concrete plug removed. One key element of the project management plan was using a contractor with extensive experience in bridges and roadwork. Not all problems can be foreseen, but if you get the project 95% planned out ,a good team can push it to 100%, working through unforeseen problems.

The old gearbox after removal, note the condition due to years of road salt dropping down from the bridge deck.

The new gearbox installed with new mounting brackets, pinion, bearing and coupling. A new stainless steel cover was later instlled to deflect road salt from the bridge deck. The work was completed in time for the summer boating season to begin and the bridge opeed without problems.