Geometric Dimensioning and Tolerancing

Geometric Dimensioning and Tolerancing - Thats something is something only engineers use ?

GDT&T attempts to pull together design, drafting, manufacturing and production so that they all work together toward a common goal - "Producing parts that fit together" first time and every time.

This goal is never more important now that the person who designs and drafts the part maybe thousands of miles away from the shop that ultimately makes the part. The maker of the part, may not even speak the same language as the designer making the drawing the only viable means of communicating how the part is supposed to be made.

Old fashioned coordinate toleranced drawings are simply not good enough in this sort of environment. While they may adequetely communicate the size and shape of the part, coordinate dimensions dont make it clear how the part is inspected. What are the most important dimensions.

Coordinate dimensioning and tolerancing may lead to parts being having faces machined unneccessarily and at extra cost. It may also result in ambiguous instructions for inspection where bad parts end up being accepted and good ones end up being rejected.

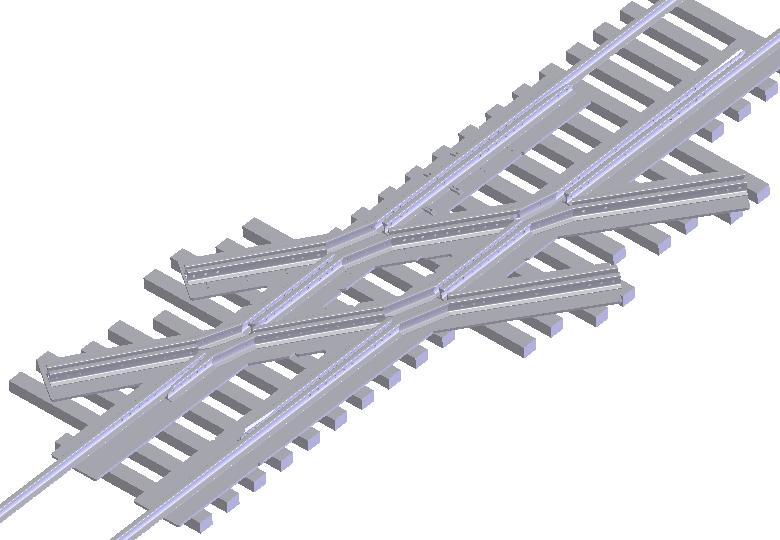

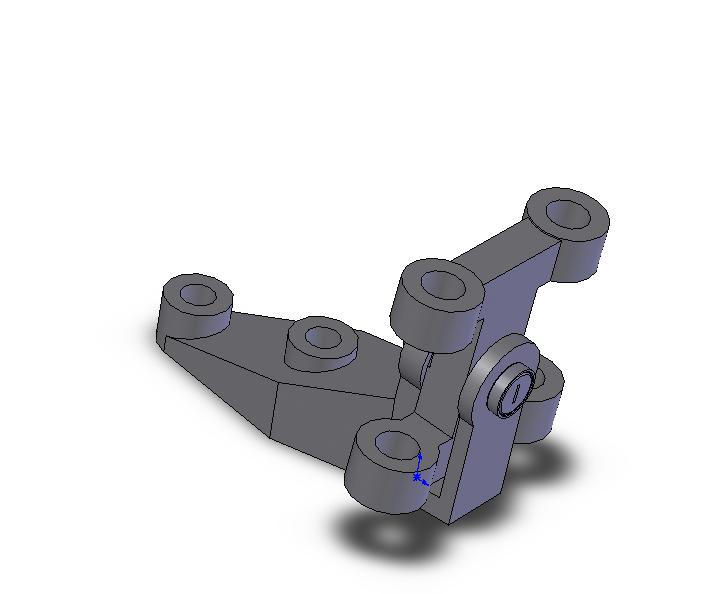

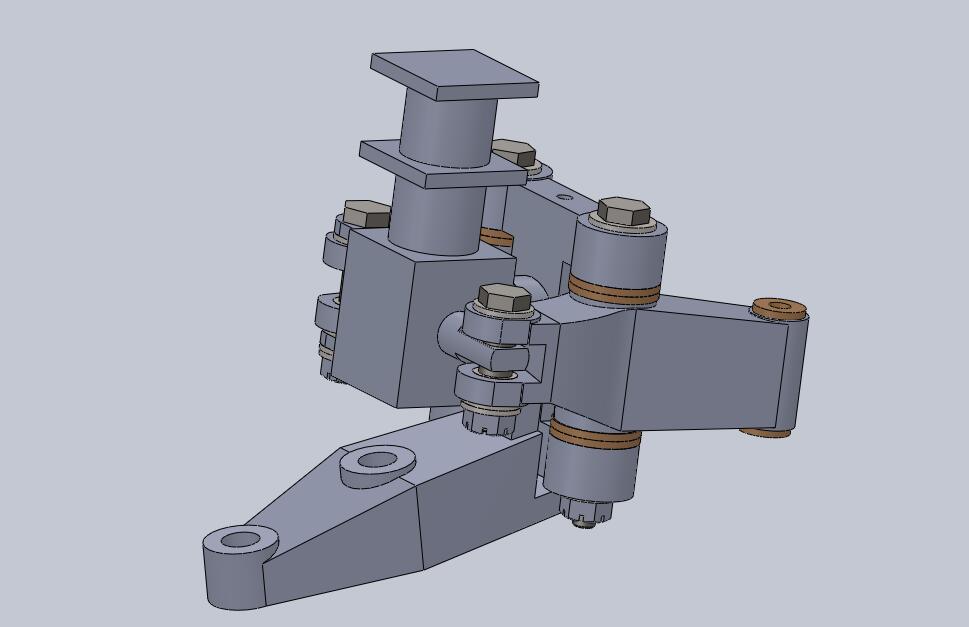

Perhaps the most important part of the GD&T dimensioning system is in ensuring parts go together by identifying the critical features. Take for example this railroad car disk brake assembly.

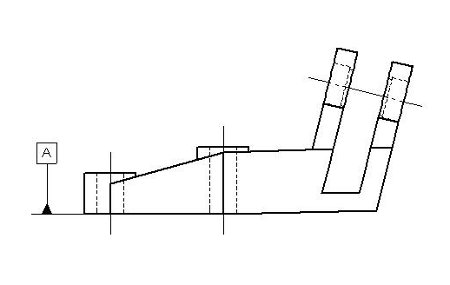

If we were going to be preparing the machining drawings for the base component for this disk brake, It is reasonably certain that the flat face on the base would be our primary datum. This is the face where the disk brake assembly attaches to the train.

Just by doing this we have not only identified the most important surface but also communicated to inspection that this ought to be the reference surface used to check the position and characteristics of all bolt holes, and machined features.