Rooftop Solar Panel Mounts

Rooftop solar panel mounts are necessary when installing a solar panel system. There are things you should consider when mounting any solar installation on a flat roof building.

Firstly you will need to get a structural engineer to examine the roof and determine if your roof can support the solar PV installation.

The weight is usually not a big problem but the wind load could be. Rectangular rooftop solar panels can act like a sail and transmit a lot of force through its connections to the roof. Snow load needs to be checked in cold climates. A heavy load of snow buildup on a solar panel can damage the panel and possibly add more load to the roof than it was designed for.

Once the engineer has checked the load conditions they will likely specify the support locations penetrating the roof membrane that will be used to carry the framework supporting the solar panels. Supports that penetrate the rood membrane are potential sources of leakage, so their quantity needs to be kept to a minimum.

With the solar panels covering these supports, access for maintenance may not be easy. All steps need to be taken to make sure these penetrations will not compromise an existing leak free roof.

Once the roof supports are in place the rooftop solar panels support structure can be installed. These usually consist of lightweight aluminum structural components such as channels and box sections. They are long aluminum clamping rails which are used to attach the solar panels themselves. The panels are laid across the clamping rails and bolted in place with clamps that grip adjacent panels.

One more consideration is protection from fire. Solar panel installations can carry a lot of current, and a short circuit could cause a large heat buildup and potentially fire. The help of an electrical engineer to safeguard the roof from potential electrical hazards maybe warranted in large solar panel installations. This might involve installing additional fireproofing and electrical insulation in high risk areas.

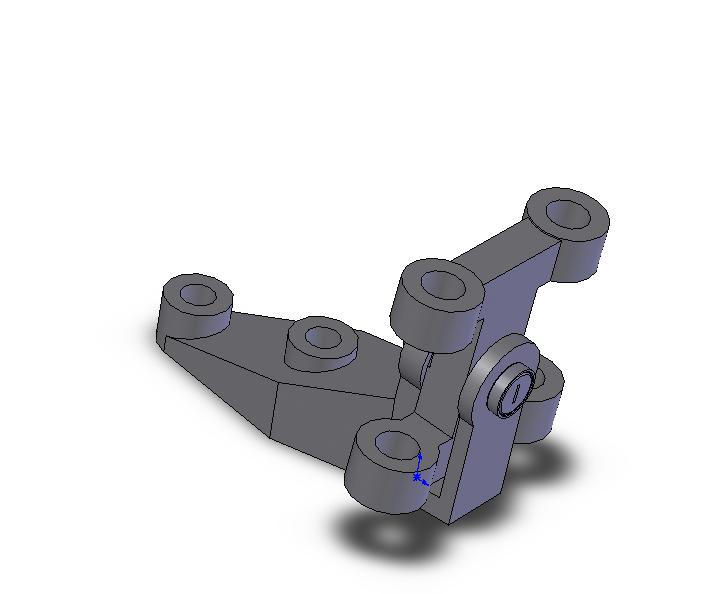

Solar panel mounts available on Amazon

These rooftop solar panel mounts have favourable review although some have complained about the T-Nuts bottoming out. This could be due to difficulty in getting the frame plumb and square due to the type of roof involved. As for the mounting of the angle brackets, you not only need to know the type of roof but how the existing roof was installed.

For example mounting the angle brackets on a steel roof may be difficult. Steel roof panel are often mounted to equally spaced furring strips with an air gap in the voids between the furring.If you try to locate one of the brackets between the furring strips you wont be able to tighten it down properly unless you use a bushing the same thickness as the furring.

Installation on regular shingle roofs will not be a problem because there is no air gap and you can screw through the plywood substrate and into the wood joist. Shingled roof surfaces can be very uneven and so angle brackets should be secured with gasketed self sealing fasteners to prevent leakage. A rubber gasket or sealant underneath the bracket would be a good idea too.

Tile roofs, both steel and ceramic require the tiles to be removed and the brackets installed onto the roof deck, then the tiles cut around the bracket and flashed and caulked to prevent leaks.

Wind load and weather conditions can cause brackets to shift slightly and caulked joints to open and crack. Making holes into a perfectly good roof for brackets opens up the potential for future leaks. Repairing the roof and removing and replacing the solar panels as well is a lot of work so all possible steps need to be taken so that brackets are properly sealed.

Return from rooftop solar panel mounts to the home page.

return from rooftop solar panel mounts to the Architectural Drafting section.