Rapid Prototyping processes for everybody

Rapid prototyping processes are putting more power in the hands of designers and inventors alike. In the past, if you invented a new product, the options for proving it out were very expensive. You could try and build a prototype yourself if you had the necessary skills or you had to engage a small army of toolmakers, machinists and assemblers. Either way you could be looking at spending a fortune. Edison made thousands of prototypes and years of work before his light bulb was perfected.

These days 3D Printing machines put plastic rapid prototyping power in the hands of anyone. As long as you have a suitable 3D model, created by any one of a number of suitable software systems, creating a prototype of your invention is as simple as pressing print.

3D Printers push a printing medium through a print head much like how ink is sent through your desk printer. Instead of ink, the liquid is a special polymer which deposits on a flat surface inside the printer. Machines such as the Connec500 manufactured by Objet use polymers which harden in the presence of UV light.

Other types of rapid prototyping processes include FDM machines or fused deposition modeling. The Stratsys company own the patent to this technology. FDM machines use spools of polymer wire which is fed into the printhead and heated into liquid form where it can be applied by the printhead.

Printers such as those made by the company Z-Corp lay down layers of powder and then include a pigmented glue. This is the only method that allows printing in full or actual part colours. Another company, Viper Stereolithography, has its machines use only UV light hardening a specific film over the surface of a photo polymer liquid. The film is allowed to sink and more film is hardened on top. As the part descends it ends up totally immersed in liquid and at the end the liquid is drained for a dramatic part reveal.

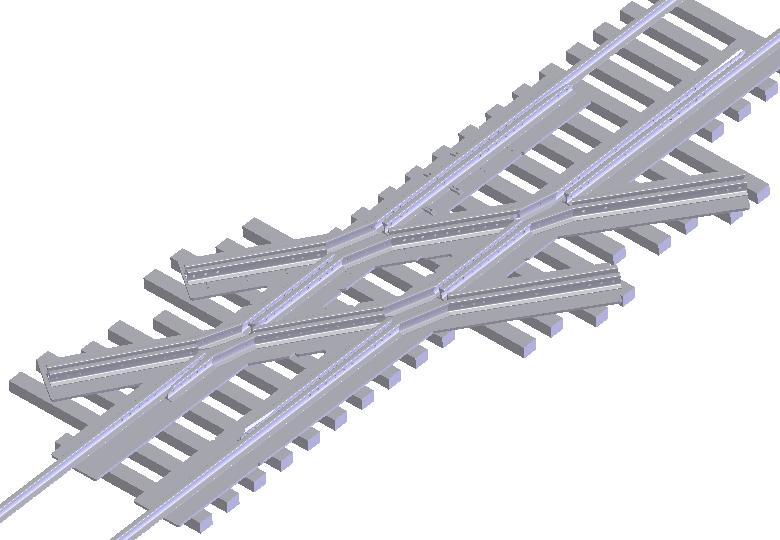

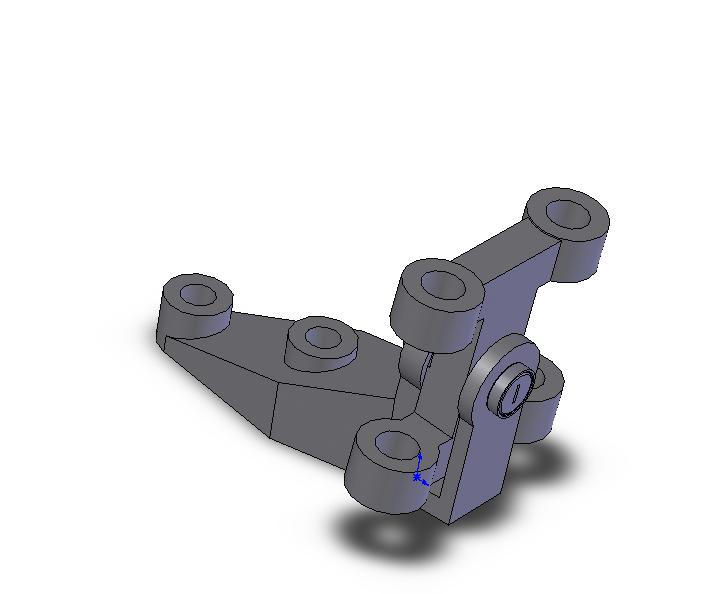

The roller chain above is an example of a rapid prototype part. This chain was printed in one assembly ready to be installed to test for fit. The only preparation after printing was cleaning the support media out of the chain using a waterjet or air blast.

Objet machines currently focus on machines which fabricate prototypes. Some 3D printers are currently capable of printing actual parts. The 3D Sinterstation SLS use rapid prototyping processes called selective laser sintering which replaces the UV light curing method with a powerful laser capable of sintering custom materials such as stainless steel. It is one technology that can be used to produce actual components. In the future, the number of materials available for actual part production can only increase.

Laminated Object manufacturing LOM is an example of rapid prototyping processes where the machines cut and stick flat sheets of material to form objects sort of like a very sophisticated kind of paper mache. MCOR Technology is a company that has released a new 3D printer that uses paper as the build medium.

To accomplish high accuracy 3D plots down to a 16 microinch finish, the Objet uses a multitude of 8 micron printheads. The resulting printed finish is as good as could be achieved by CNC machining and polishing.

The print liquid is proprietary, and is used by all of Objets machine. You cannot substitute another manufacturers printing medium. The machines also use a Support medium is used to form an expendable support for model features. The amount of liquid used on a given model can vary by the skill of the machine operator. By reorienting or sectioning the model, an operator can reduce the amount of support medium required. Once the final model is created, it should be possible to estimate cost based on material usage.

The machine facilitates scaling to allow the user top print out a part in large format then scale it down once all the fit and clearance issues have been seen to. 3D printing is a great boon to manufacturing tiny parts, since there may be no other method to economically produce small assemblies. Examples of micro machines might be model helicopters, or even inspection robots.

Small parts also have the benefit that existing protoyping materials may be strong enough to resist the forces such that actual working sell-able products can be produced.

3D printing can be used to produce fully functional assemblies such as roller chains and belts made precisely to the right size for test mounting on original equipment. It is also useful for making artistic works which subsequently become positive mould for RTV silicone moulds. RTV moulds are often used to make production parts in low quantities, perhaps 50 to 100 parts at a time. The same method could also be used to produce hard to find parts which are no longer manufactured yet needed on an occasional basis.

Objet machines can in a variety of sizes from desktop models to floor machines. The smallest desktop machines are restricted to producing prints in hard plastic medium. As the machines get larger, more features are added. Such as the ability to print dual materials in a single part. This would be necessary to create parts in dual durometers or parts with what are called living hinges.The largest machines can handle a wider variety of mediums, including transparent materials as well as materials of varying hardness and strength.

The snap lid box above was made using dual durometer printing to make a box with strong sides but with soft "living hinges".

Applications for 3D printers and new rapid prototyping processes are expanding as the general public discovers their capabilities. Surgeons can have 3D prints made of body organs for their training and development. Bakers can used 3D printers to print logos inside loaves of bread.