Drafting of Dust Collector Accessories

dust collector accessories have to be considered when drawing up the dust collection system in a large industrial plant or commercial woodshop. Dust collection systems have key componenets like afterfilters, slide gates and various types of hoods all of which are critical in the proper operation of the system.

Dust Collector Fittings

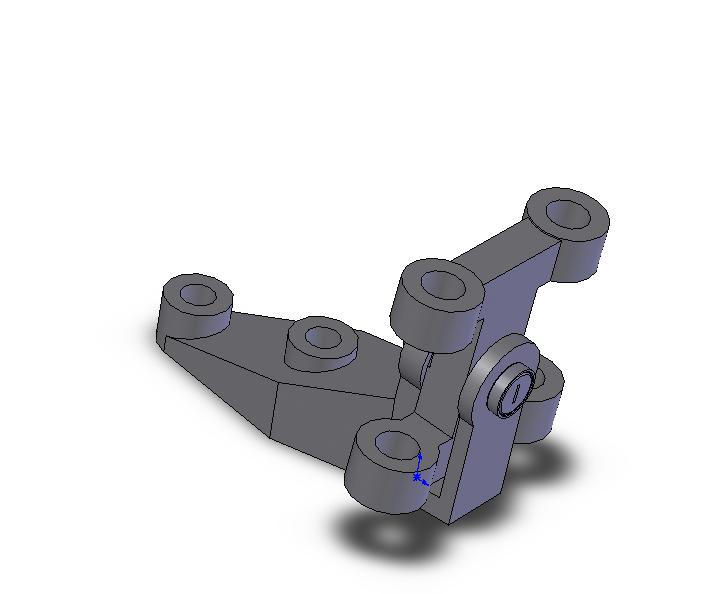

Dust collector fittings consist primarily of different types of hoods which pick up dust from the various manufacturing operations. Simple fittings like hoods, flanges and slide gates are usually purchased items which can be specified on the drawing. It's always best to search for fittings that can be bought off the shelf, rather than have them custom fabricated. Making them usually ends up being a lot more expensive.

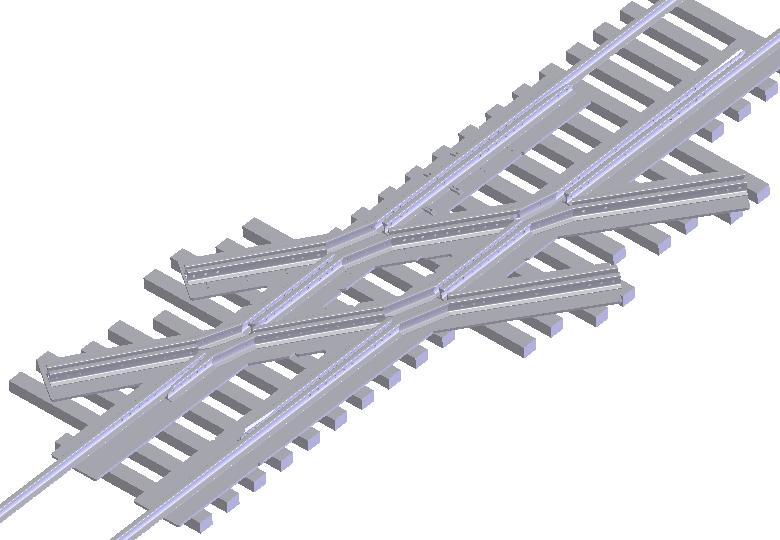

Other times there may be special duct fittings like pantleg wyes which have to be detailed for the sheet metal shop to fabricate. These items require the draftsperson to have experience in sheet metal layout so that they are designed in the most cost effective way to manufacture. To gain this kind of experience you usually have to work closely with the sheet metal fabricator to learn the way he likes to do things. In sheet metal fabrication, there are often many "right" ways to achieve the same result.

Dust Collector Bags

Dust collector bags are generally used in large industrial baghouses. These are huge dust collectors where the bag works in a very similiar way to the bag in your vaccuum cleaner. Dust and dirt collects on the bags as the system is in operation. Older baghouses use mechanical "shaker" systems to shake the dust off the bags from time to time. This prolongs the life of the dust collector bag by stopping the dust buildup. Newer baghouses use powerful jets of compressed air, blown though venturis at the top of the bags to accomplish this.

Draftsmen working on baghouse projects often need to specify the bags. For example fire regulations may force the use of Nomex fire retardant bag material. Bags are also available in various filter media with differing particle size specs. The designer also has to know about pneumatics in newer baghouse systems because these systems use an enormous amount of compressed air to clean the bags. There are specialized air valves and header piping arrangements necessary as well as the need for seal welded enclosures to keep everything air tight.